Since the barrel is pressed in, rather then threaded, it is possible to press the barrel so the gas block and the front sight is not aligned with receiver. This would be troubling mistake, as you would need to figure out a way to press the barrel out, adjust the timing and press it back in again.

I won’t lie, this has been something I have been thinking alot about. How to properly time this barrel to the receiver is something I’ve really tried to think out. I haven’t seen a lot written on it. This is what I’ve come up with, and we will see if it works.

I took a model of the VZ-58 Receiver, barrel and front sight and assembled them in CAD. This allows me to play around with the jig design to troubleshoot the design prior to actually cutting any metal. The design I came up with is a simple piece of flat stock that aligns the front sight with the front of the receiver. From there I can put timing marks on the barrel and receiver.

When I go to press the barrel into the receiver these timing marks will allow me to align the barrel to the receiver, and make sure the barrel and receiver does not rotate during the press. Since this will be a straight press, I do not expect any rotation, but stranger things have happened.

The jig itself I’ll construct from aluminum flat stock. The drawing I put together will be drawn at a 1:1 scale. When I print out the drawing, I can cut out the design and paste it right to the metal and use that as a guide. As long as the printer doesn’t scale the drawing it is a handy trick that simplifies layout.

Using the drawing as a paper template is one of my favorite tricks for roughing out a part.

It was frustrating to spend 45 minutes on a jig that was far too short. As I write this, I can think of a few things that I could have done to prevent this from happening. I very nearly made the same mistake again in constructing the new part.

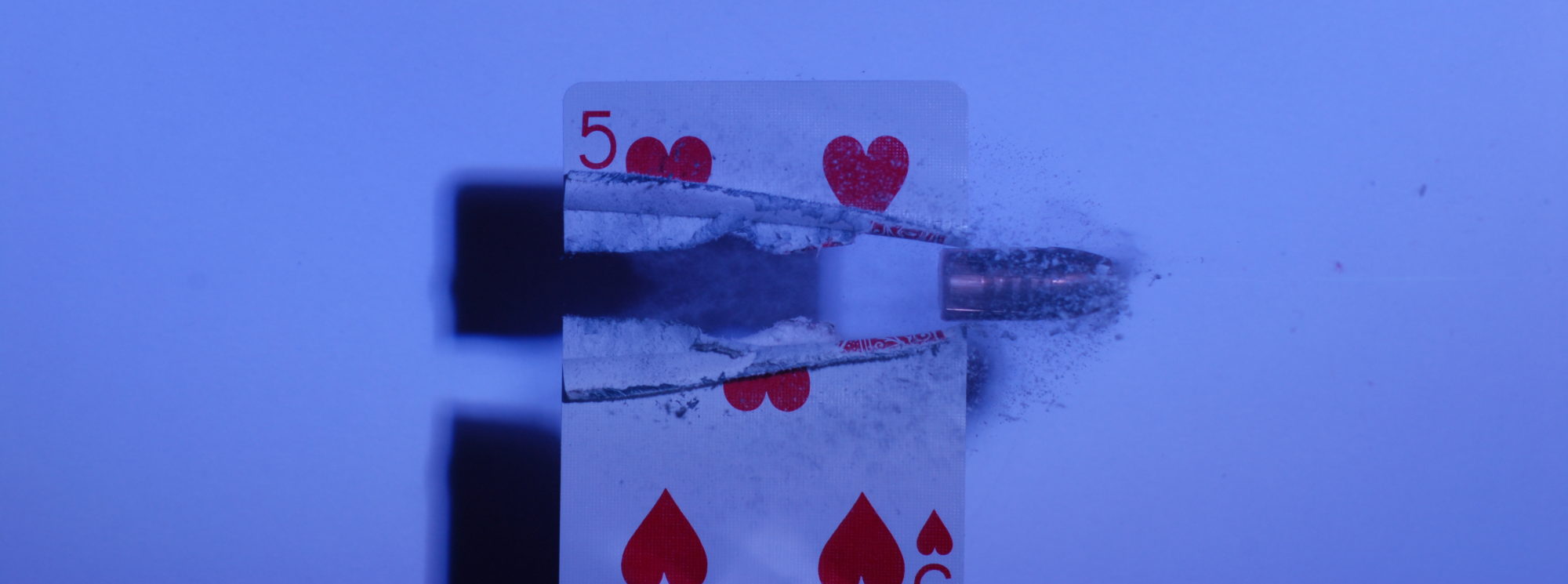

Once I had the jig inplace I came to the realization that I didn’t need to have the long notch in the jig at all. I simply made a few timing marks on the receiver and the barrel with a Sharpie. Apparently I forgot to take a photo of these marks, but you can see an example in the photo below.

Once the jig was done and we were able to make the timing marks on the receiver we were done. At this point all the jigs and fixtures had been made and we are ready to press the barrel into place. As far as design changes to the timing fixture, they are reflected in the drawing image and PDF included below.

There are other ways that the barrel may be time to the receiver. I discovered those after I completed the task. Both of these alternative methods are used to align the barrel and place witness marks on the receiver and the barrel.

You could use a long plug to align the gas block with the receiver. It would need to be a tight fit on both ends but it would do the job.

You could also use a level on the receiver and on the bayonet lug. As long as the sight was pointed in the right direction if both the receiver and the lug are parallel (level) then in theory the barrel should be indexed correctly.

Hope this has been helpful, and it shows that there is more than one way to skin a cat.